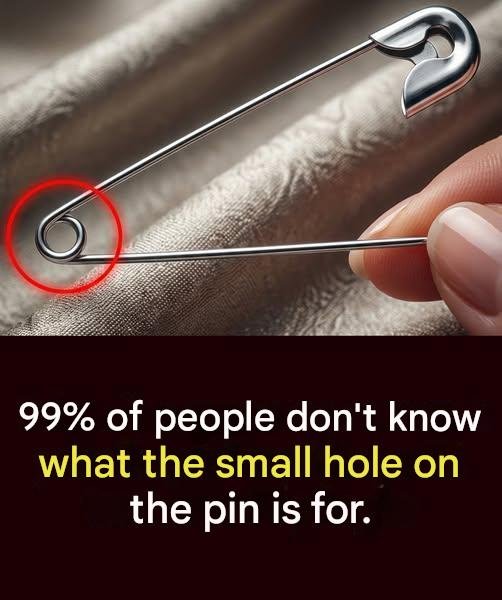

The True Purpose of the Small Hole on the Pin

You’ve probably seen it a hundred times without giving it a second thought: the tiny hole at the base of a pin. Whether it’s on a sewing pin, a safety pin, or a pushpin, this minuscule feature is often overlooked. Yet, it serves a very deliberate purpose, combining both practicality and safety. In this article, we’ll explore why that tiny hole exists, how it enhances your everyday tasks, and why pin manufacturers include it in the first place.

What Exactly Is the Hole on a Pin?

The small hole on a pin is usually located at the base of the head or at the shaft, depending on the type of pin. It is tiny, sometimes hard to notice without close inspection, but it has a crucial role. While at first glance it may appear to be a manufacturing leftover or purely decorative, the reality is far more practical.

Pins come in various shapes and sizes, including sewing pins, safety pins, and decorative pins, but nearly all types share this tiny hole feature. The hole is most often circular, and its purpose is tied to structural integrity, safety, and functionality.

Historical Context

The design of pins has been refined over centuries. In the early days of sewing and tailoring, pins were hand-forged from wire. With industrialization, machine-made pins became widespread, and engineers began experimenting with minor design tweaks to improve durability and ease of use.

The small hole was introduced during the late 19th century, primarily on sewing pins, to reduce material waste during manufacturing. However, manufacturers soon discovered that this tiny feature provided multiple additional benefits beyond production efficiency.

The Primary Purpose: Safety

One of the main purposes of the small hole on a pin is safety. The hole reduces the risk of the pin splitting or bending under pressure. Here’s how it works:

-

Stress Distribution: The hole helps distribute stress along the pin shaft, preventing cracks from propagating. When the pin is pushed into thick fabric, the stress tends to concentrate at the tip. The hole acts as a “stress reliever,” making the pin less likely to snap.

-

Preventing Head Separation: On pins with plastic or metal heads, the hole allows adhesive or molten material to lock into place more effectively during manufacturing. This prevents the head from separating, which could cause injury during handling.

-

Improved Flexibility: A pin may need to bend slightly without breaking. The hole slightly reduces material density at the right spot, giving the pin flexibility without sacrificing strength.

In short, that small hole is a safety feature that prevents accidents and makes the pin more reliable.

Secondary Purpose: Ease of Manufacturing

The small hole also has practical benefits for production efficiency:

-

Material Saving: By removing a tiny amount of metal, manufacturers save resources over large-scale production. Though each individual hole uses very little metal, production in the millions adds up.

-

Better Plating or Coating: The hole allows electroplating or paint to adhere more evenly on the pin, ensuring a consistent finish that prevents rust and corrosion.

-

Mechanical Grip: When the pin is mechanically assembled or mass-produced, the hole can be used to align or hold the pin during automated processes, making the assembly faster and more precise.

So, the small hole isn’t just an accident of design; it’s a manufacturing optimization.

Hidden Benefits You Might Not Know

The hole also provides some unexpected advantages:

-

Thread Holding in Sewing: On some specialty pins used in sewing or quilting, the hole can slightly catch a thread or small fiber, preventing the pin from slipping out while working.

-

Marking & Measuring: In industrial settings, the hole can be used as a reference point for precision tools, aiding in accurate positioning or cutting.

-

Decoration: For decorative pins, such as brooches or lapel pins, the hole allows artisans to attach tiny gems, enamel dots, or beads, adding aesthetic value without increasing the weight of the pin.

Even though these advantages are secondary, they illustrate how a tiny feature can have multifunctional purposes.

Common Misconceptions

Many people assume the small hole is either:

-

A manufacturing defect, leftover from the stamping or molding process.

-

Purely decorative, meant to make the pin look more refined.

Neither assumption is entirely correct. While it may appear insignificant, the hole is intentionally designed to enhance performance, safety, and manufacturability. It’s a small, clever engineering solution that often goes unnoticed, yet is present in nearly every high-quality pin.

Tips for Everyday Use

Understanding the purpose of the hole can even affect how you use pins:

-

Avoid forcing pins into surfaces that are too dense. The hole helps, but excessive force can still bend or break the pin.

-

When sewing, insert pins so the head is facing up, allowing stress to distribute along the shaft more evenly.

-

For decorative pins, use the hole to secure embellishments if you’re doing DIY jewelry or craft projects.

Conclusion

The small hole on a pin may seem trivial at first glance, but it’s a smart design feature with multiple purposes:

-

Enhances safety by reducing breakage and distributing stress.

-

Improves manufacturing efficiency and material use.

-

Provides subtle additional benefits like thread holding, decoration, and alignment during production.

Next time you pick up a pin, take a moment to appreciate this tiny engineering marvel. That little hole is proof that even the smallest details in design can make a huge difference in safety, usability, and craftsmanship.

In essence, the next time someone dismisses a pin as a simple piece of metal, you’ll know there’s a lot more going on in that tiny, unassuming hole than meets the eye.